Live Webinar | 19.02.2026 | 09:00 CET

Smarter Extrusion Die Design with

Automated Cloud Simulation

Designing extrusion dies for homogeneous flow, stable throughput and high product quality is increasingly challenging – especially with complex geometries, demanding materials and limited engineering resources.

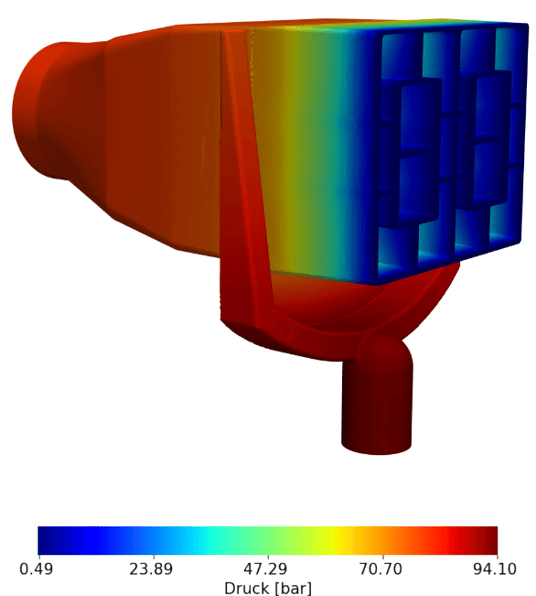

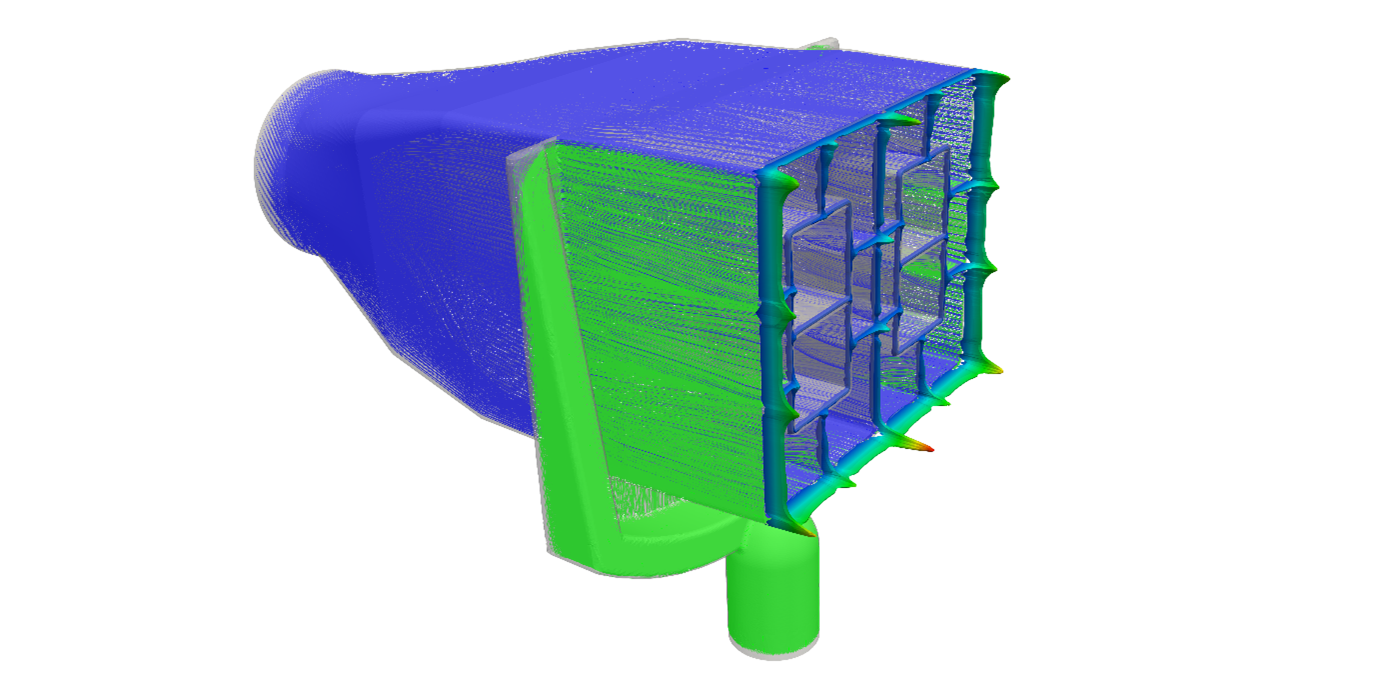

In this webinar, we introduce StrömungsRaum® Extrusion, the automated extrusion die simulation solution within the StrömungsRaum® platform. It enables precise, cloud-based flow simulations of extrusion tools – including pressure loss, velocity distribution and residence times – without the need for local hardware, simulation software or CFD expertise.

You will learn how extrusion tools such as profile dies, flat dies, spiral mandrels or elastomer dies can be analyzed and optimized virtually within minutes, reducing physical prototyping, scrap rates and development time while improving process stability and product quality.

In this 30-minute webinar, we show how StrömungsRaum® Extrusion supports engineers, developers and decision-makers in optimizing extrusion dies through fully automated cloud simulations.

After a short introduction to typical challenges in extrusion die design – such as inhomogeneous outlet flow, pressure imbalance or long iteration cycles – we demonstrate how StrömungsRaum® Extrusion addresses these issues with a standardized, simulation-driven workflow.

A live demonstration illustrates the complete process: from uploading the die and defining material as well as process parameters to interpreting simulation results in intuitive reports.

Real industrial use cases from elastomer extrusion, profile extrusion and multilayer applications highlight how companies reduce trial-and-error, stabilize processes and accelerate tool development. The webinar concludes with a Q&A session to discuss individual application scenarios.

The learning objectives:

- Understand extrusion die flow behavior early

Learn how StrömungsRaum® Extrusion enables fast and realistic prediction of flow distribution, pressure loss, shear rates and residence times in extrusion tools – before manufacturing the first prototype. - Leverage automated cloud simulation without CFD expertise

Discover how fully automated workflows and cloud-based HPC make advanced extrusion simulations accessible to everyone – without local software, hardware or simulation know-how. - Control critical effects such as wall slip and outlet homogeneity

See how integrated wall slip modeling and outlet flow analysis help identify critical zones, reduce surface defects, stabilize throughput and improve product quality.

Who is this webinar suitable for?

-

R&D Engineers / Development Managers

You are responsible for designing and optimizing extrusion tools under tight timelines and increasing complexity. Learn how StrömungsRaum® Extrusion reduces physical prototyping, development loops and dependency on scarce expert resources. -

Process & Application Engineers

You work close to production and materials and need stable, reproducible extrusion processes. Learn how simulation-based insights help optimize flow behavior, reduce scrap and shorten ramp-up times. -

CTO / Engineering & Technical Management

You are responsible for efficient use of engineering resources and technological competitiveness. Learn how automated simulation lowers development costs, accelerates time-to-market and supports scalable innovation.

.png?width=300&height=300&name=Design%20ohne%20Titel%20(28).png)